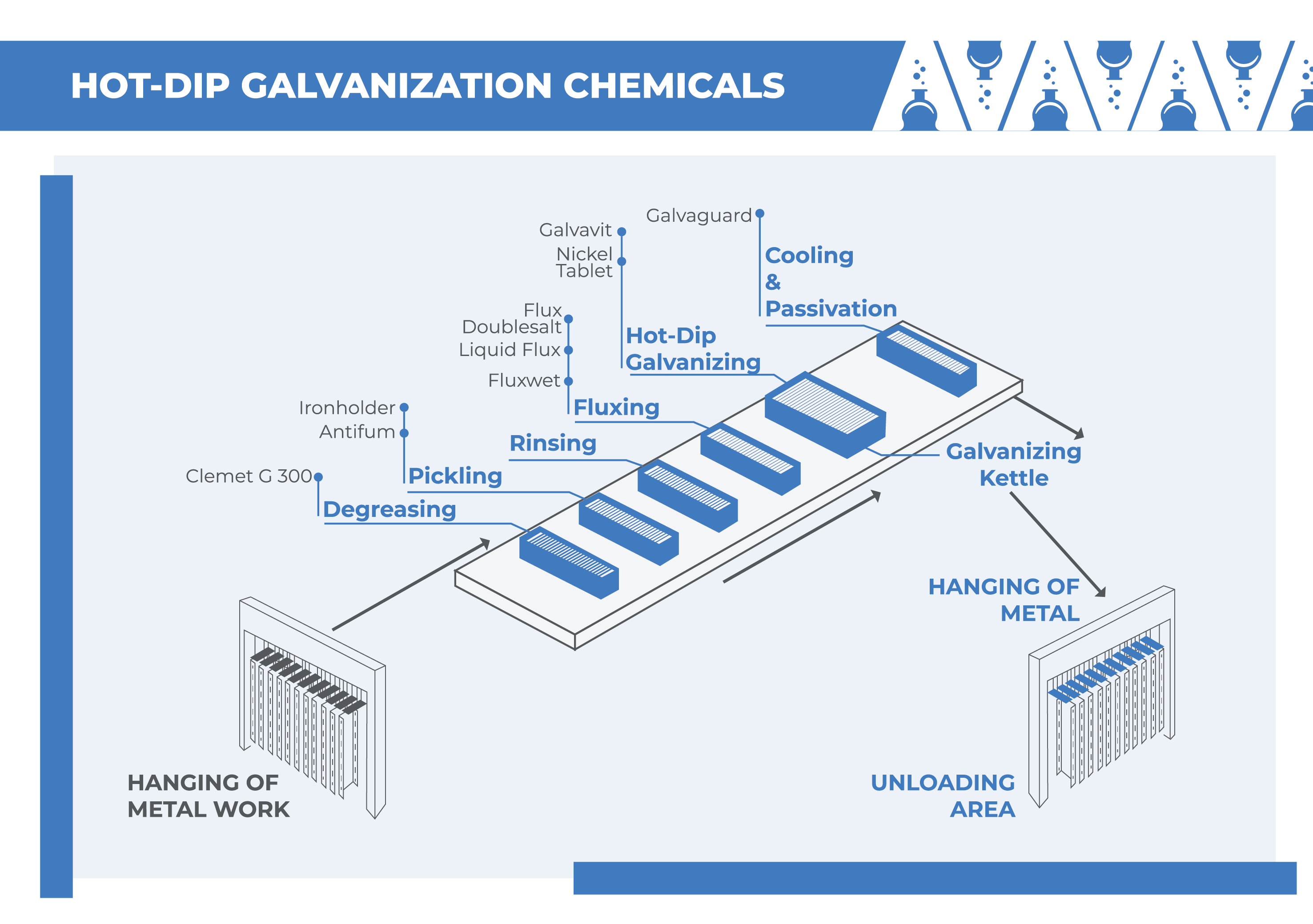

It is a single-component new generation degreasing chemical that is used with dipping method to clean iron and steel parts. It quickly cleans the grease on the materials to remove the grease completely. It is a product with inhibitor addition and phosphoric acid, therefore over-wearing of the metal pieces is prevented during the acid cleaning process; the bathing effect becomes long-lasting. After the degreasing process, the materials can be sent to hydrochloric acid or sulphuric acid bathing processes. Bathing control is simple.

It is produced to be used for hydrochloric acid bathing processes. It prevents the over-wearing of the steel during the cleaning of steel, iron and cast pieces that are processed with acid baths. A homogeneous surface is formed on the steel that is smoothly cleaned, which ensures secondary zinc saving. It extends the usage life of acid baths.

It is used to prevent the fume emerging from the hydrochloric acid or sulphuric acid baths. It forms a slight foaming layer on the acid bath to prevent the escape of the acid fume. It protects the environment and human health as well as preventing the facility wear caused by acid fumes.

The materials dipped into flux bath before galvanized coating are covered with flux salts. It protects the steel from oxidizing before galvanization. It ensures the steel directly contacts the molten zinc. The flux bath cleans the remaining dirt, iron, oxide, sulphides and sulphates on the steel, preventing them to be carried to the zinc furnace. It reduces the zinc ash and zinc dross. The coating thickness can be reduced significantly. It increases the process speed. It improves the coating quality.

Our liquid form flux product contains highly pure zinc and ammonium chloride salts. Liquid flux is easy to mix within the bath. It has all the advantages of flux dust.

Fluxwet is added to the flux pool with 0,5% concentration. The main purpose is to adjust the surface tension and to minimize the unnecessary flux consumption. It minimizes the crystallization thickness to create homogeneous coating. This formation accelerates the reaction of molten zinc to ensure whole surface is coated.,

Nickel tablet provides up to 15% zinc-saving. It prevents the effects of silicium and phosphor on the coating thickness to ensure a coating thickness according to the standard. It provides a bright and smooth coating surface. It improves the bath viscosity. It minimizes the regional coating differences. It ensures a homogeneous appearance.

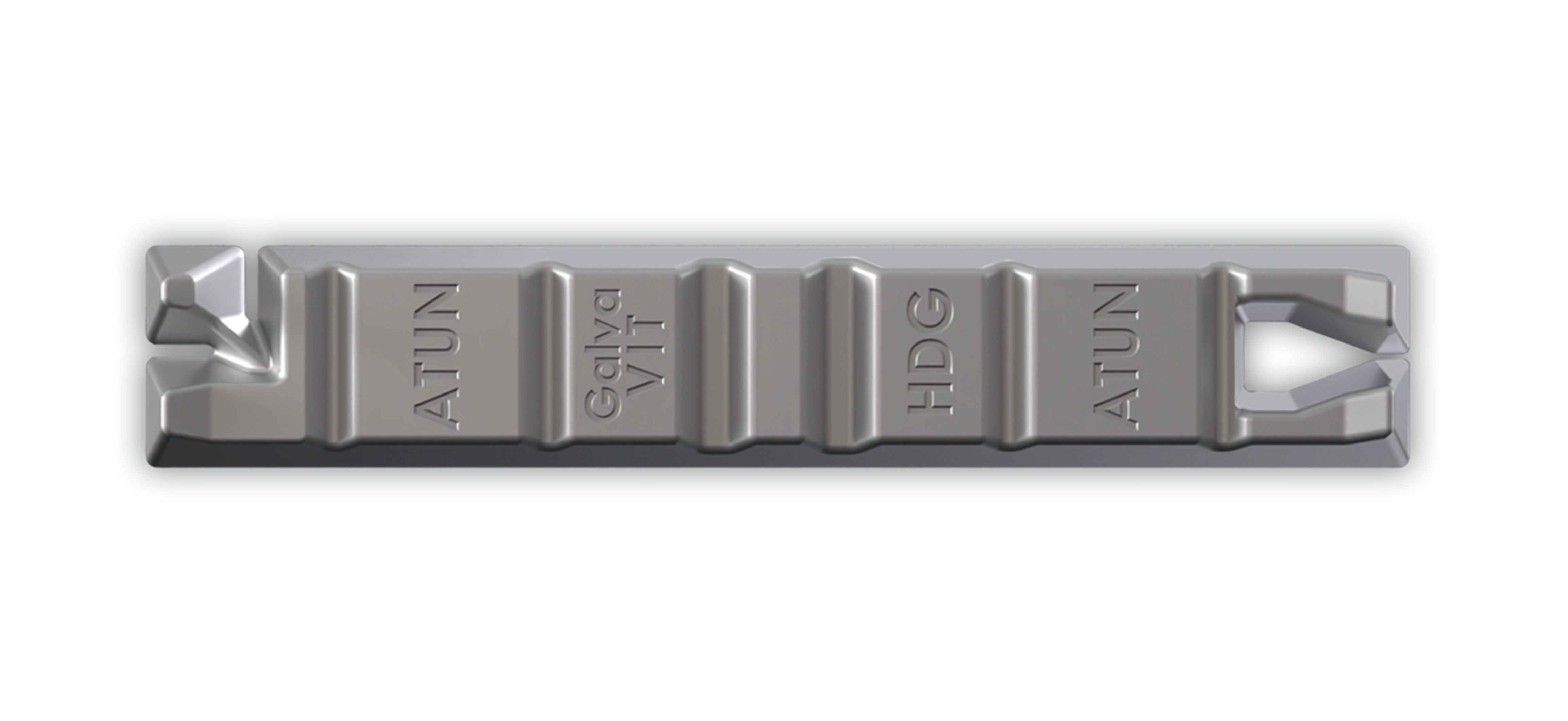

GalvaVIT, the new companion of the galvanization world, controls the furnace composition to ensure you have the best quality production in the most economic way. When used together with nickel, it controls a wider silicone equivalency range, by reducing the coating thickness of the material at silicon-equivalent ranges where nickel is not efficient to ensure your coating is according to the standard. It increases the zinc viscosity to prevent zinc accumulations on the materials as well as zinc sagging.

The main purpose of processing the hot-dipped galvanized parts in passivation pools after galvanization, is to prevent white oxidization and to prevent the corrosion until the material switches to cathodic protection, as well as to preserve the brightness of the product. It is a totally organic product.